Laminate flooring will receive an AC Rating based on their performance under a multitude of key stress points:

staining, impact, heat, moisture, scratches and scuffs. How well a particular laminate floor performs under

each test will determine its ultimate AC Rating. If a laminate floor should fail any of these durability tests, it

automatically becomes uncertifiable and is then labeled as “unrated.” If a laminate flooring product you’re

looking at is listed as being “unrated,” it’s safe to say that this particular floor isn’t going to hold up well in any

situation.

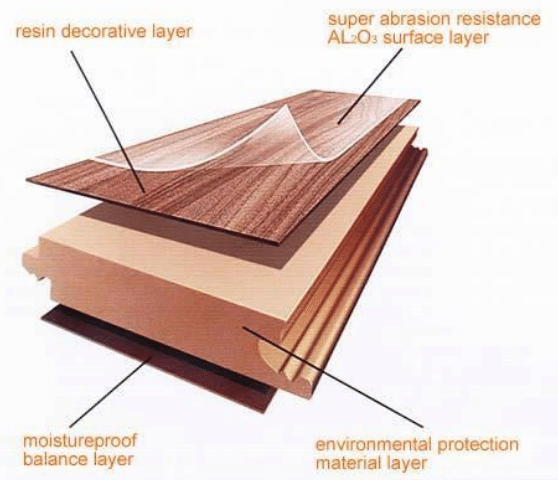

Structure

Technical Specification AC4 Flooring System

Top Surface Melamine Impregnated Decorative Film. Protected by Anti Abrasive Overlay.

Core Material H.D.F. (High Density Conifer Fiberboard) with an average density > 850 kg/m³

Thickness. 12mm + 2 mm Silent Pad.

Length. 1212mm.

Width. 127mm.

Fit for use Grading AC4/W32 EN 13329 compliance.

Installation method Interlocking (Glue less Installation)

Article

1. D108-9

2. D141-B5

3. GH-2005

4. 915

5. GH-2006

6. GH-2001

7. 630

8. 605

9. 042

10. D254-7

11. 123

What is an AC Rating?

A testament to the durability of a laminate floor is the Abrasion Class it is certified under. The Abrasion Class is

more commonly referred to in the laminate flooring marketplace as the AC Rating. The AC Rating system was

first created by the Association of European Producers of Laminate Flooring (ELPF) but ultimately became the

standard rating system for laminate flooring products worldwide. The AC Rating is a good gauge as to how well

a laminate flooring product will perform in your residential or commercial setting, so it’s a good idea when

you’re browsing through laminate floor options to know what the AC Rating for each is.

A general guide to AC ratings:

The AC rating assigned after testing specifies the level of stress and the suitable location for the laminate

flooring to be installed. These ratings will also tell you if the laminate flooring can be used in residential or

commercial areas.

AC1 Moderate Residential.

Built to withstand only light residential use. Suitable for closets or bedrooms.

AC2 General Residential.

Builtformoderate foottraffic. Suitable in residentialspacesthat don’t see a tremendous amount of wear and

tear like dining rooms or living rooms.

AC3 Heavy Residential/Moderate Commercial.

Built for all kinds of residential use including high–traffic rooms and even commercial spaces that have light

traffic like offices without off-street traffic and hotel rooms.

AC4 General Commercial.

Built to withstand every kind of residential use as well as more heavily trafficked commercial spaces that have

off-street traffic like offices, cafes, and boutiques.

Technical Data:

| TEST | STANDARD | CHARACTERISTICS/ RESULT |

| Behavior to impact Load. | EN 13329 | IC 2 – height of fall 1700 MM is the maximum height without damage (1750 MM Height). |

| Behavior to Abrasion | EN 13329 | AT> 4000 Revolutions. |

| Behavior to Scratching | ISO 1518 | > 25N |

| Insensitivity of wear layer to stains | EN 438.2.15 | Rating 5 (no effect). |

| Porosity | Graphite test 1 | Grade 1 (Pore-free) |

| Light fastness/UV resistance | EN 438.2.6 | Level 6 (Blue Wool Standard) Note: Changes are measured against blue scale. Grade 6 = No Change. |

| Resistant to glowing cigarette ash | EN 438.2.18 | Degree 5: No Visible Changes. |

| Formaldehyde Emission | E.T.B. Regulation | Measured in Permissible P.P.M. Emission. Approved and Test at Quality E 1. |

| Waste Disposal | N/A | Residual materials disposable with domestic waste. No Toxic fumes released during thermal disposal. |

| Fire Classification | DIN 4102 | Flame-Retardant – B1. |

| Ignibility | DIN 51960 | Does Not Ignite Easily |

| Smoke Development | 0 – Norm B3800/1 | Class Q1 – Low smoke development Austrian Institute for Floor Covering). |

| Indentation Test | DIN 51955 | Residual Indentation 0.0 mm (I.B.A – Koblenz). |

| Chair Castor Test | DIN 54324 | No Negative changes when using soft wheel castors Type W (I.B.A. Koblenz) |

| Susceptibility to Cracking | EN 438-2.26 | No Cracks Observable. Specimen is Subjected to Large Temperature Change |

| Simulated pushing of Furniture leg. | EN 424 | No visible damage. |

| Thickness swelling test | EN 13329 | < 18% swelling |

Reviews

There are no reviews yet.